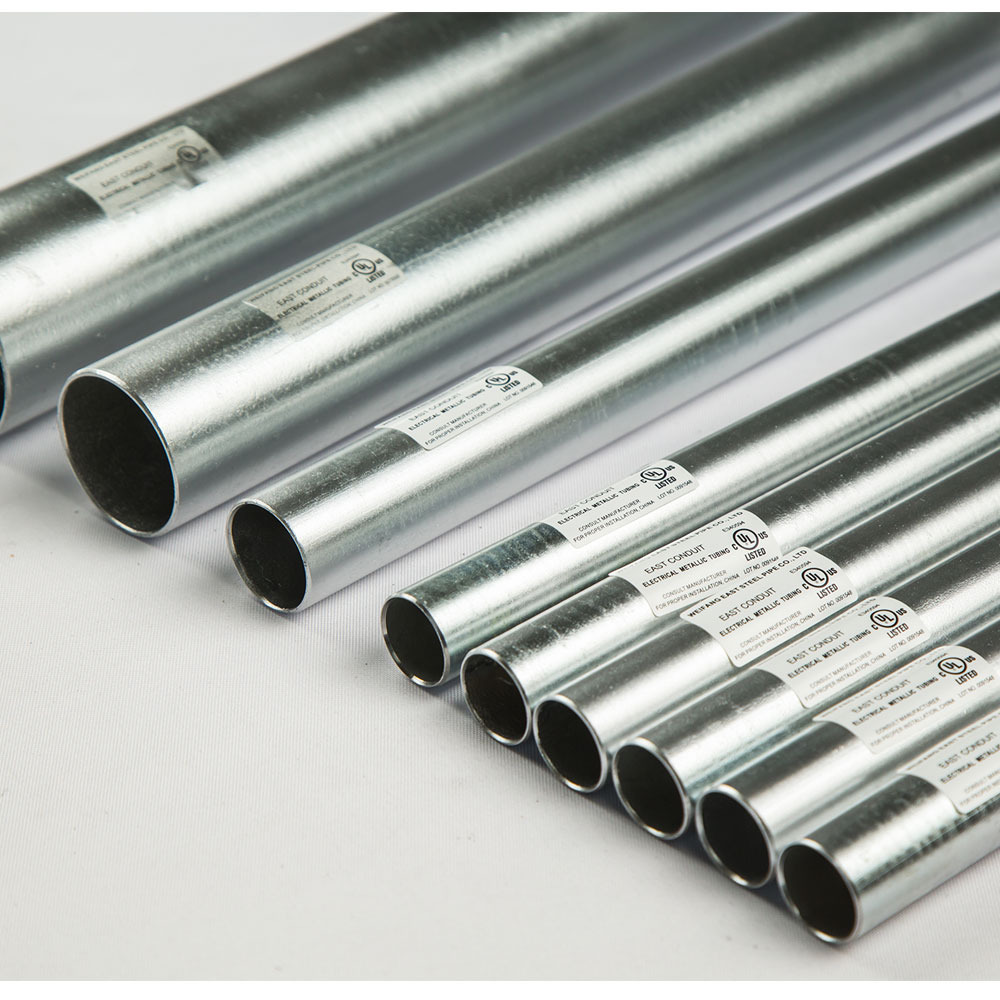

【East Steel Pipe】What is EMT elbow? What are EMT elbows used for? The welds on the inner and outer surfaces of the EMT elbow are smooth and flawless, and the hot-dip galvanizing process is applied to uniformly galvanize, so the anti-corrosion ability is extremely strong. After the EMT elbow is galvanized, the surface is covered with a transparent coating to further enhance the anti-corrosion ability. EMT elbows are processed from EMT straight pipes in strict accordance with the new version of ANSI C80.3 (UL797) standard.

1. low cost. East emt Conduit brand EMT tubing will not split, galvanize, wrinkle, or break after severe bending. The physical and mechanical properties of EMT tubing ensure that it has a long lifespan and is widely used and stocked without compromising quality. 2. Smooth inner wall. EAST CONDUIT brand EMT pipe will grind the burrs on the inner wall during the production process, and then cover the surface of the zinc layer with a layer of coating after galvanizing to ensure longer life, smoother inner wall and larger wire capacity, while ensuring the distance between the inner wall and the wire. There is less friction between them, preventing the thread from being scratched.

3. consistent quality. EMT CONDUIT brand EMT tube, has the advantages of long service life, durable, strong, suitable for bending, etc.,

Dongfang Steel Pipe has been focusing on steel anticorrosion for 30 years

And through welding to ensure that the quality strictly meets the standard quality requirements. EAST CONDUIT brand EMT pipe has no unqualified raw materials or negligent quality control during steel pipe welding, so there will be no splitting or wrinkling during bending. EMTconduit is easy to cut, shape, connect.

4. Not affected by mechanical usage and environment. The inner and outer walls of East Conduit brand EMT tubes are covered with zinc layer to ensure anti-corrosion capability.

Dimension and Weight Chart

| Trade Size | Nominal Wt. per 100Ft(30.5M) | Nominal Outside Diameter | Nominal Wall Thickness | ||||

| U.S. | Metric | Lbs | Kg | In. | mm | In. | mm |

| 1/2″ | 16 | 30 | 13.5 | 0.706 | 17.93 | 0.042 | 1.07 |

| 3/4″ | 21 | 46 | 20.7 | 0.922 | 23.42 | 0.049 | 1.24 |

| 1″ | 27 | 67 | 30.6 | 1.163 | 29.54 | 0.057 | 1.45 |

| 1-1/4″ | 35 | 101 | 45.6 | 1.51 | 38.35 | 0.065 | 1.65 |

| 1-1/2″ | 41 | 116 | 52.8 | 1.74 | 44.2 | 0.065 | 1.65 |

| 2″ | 53 | 148 | 67.2 | 2.197 | 55.8 | 0.065 | 1.65 |

| 2-1/2″ | 63 | 216 | 97.9 | 2.875 | 73.03 | 0.072 | 1.83 |

| 3″ | 78 | 265 | 120 | 3.5 | 88.9 | 0.072 | 1.83 |

| 3-1/2″ | 91 | 348 | 158 | 4 | 101.6 | 0.083 | 2.11 |

| 4″ | 103 | 392 | 178 | 4.5 | 114.3 | 0.083 | 2.11 |

Applicable Tolerances:

Length: 10Ft (3.05m) ± ¼” (±6.35mm).

Outside Diameter: ½”-2” ±0.005” (±0.13mm); 2½” ±0.010” (±0.25mm); 3” ±0.015” (±0.38mm); 3½”-4” ±0.020” (±0.51mm)