Project Description

3PE anticorrosive steel pipe is often used in water transport, natural gas, oil, heating and other industries, this product with spiral steel pipe as the base material, has the advantages of high mechanical strength and strong bearing capacity.

The outer wall of the steel pipe is made of 3PE anti-corrosion, and the bottom layer is epoxy powder, which has good chemical corrosion resistance and cathode stripping resistance. The middle layer is a adhesive, which connects the epoxy powder and the outer layer polyethylene; The outermost layer is polyethylene, which mainly plays a mechanical protection role and has anti-corrosion properties.

The production process of steel pipe adopts spiral seam double-sided submerged arc welded steel pipe. The diameter of steel pipe is DN300-DN3600, and the wall thickness of steel pipe is 5-26mm.

The connection mode is welding, good sealing, no leakage.

The pipeline has strong adaptability, strong ability to withstand deformation, seismic resistance, anti-settlement, anti-collapse.

Can be used as pipe jacking or pipe pulling, trenchless technology does not affect traffic.

Each of our steel pipes will undergo three tests, namely X-ray test, hydraulic test and ultrasonic test, to ensure that the quality of each steel pipe is qualified.

Each of our steel pipes has its own identity code to ensure the stability of quality.

We use the most advanced Lincoln welding machine, which is the most advanced welding machine at present, in addition to each of our processes to achieve the ultimate, will meet the implementation standards, we will be on both sides of the coil milling process, the use of anti-corrosion layer welding wire, to ensure the quality of the weld; Both ends of our steel pipe have been prepared with bevels, which can be welded directly at the project site.

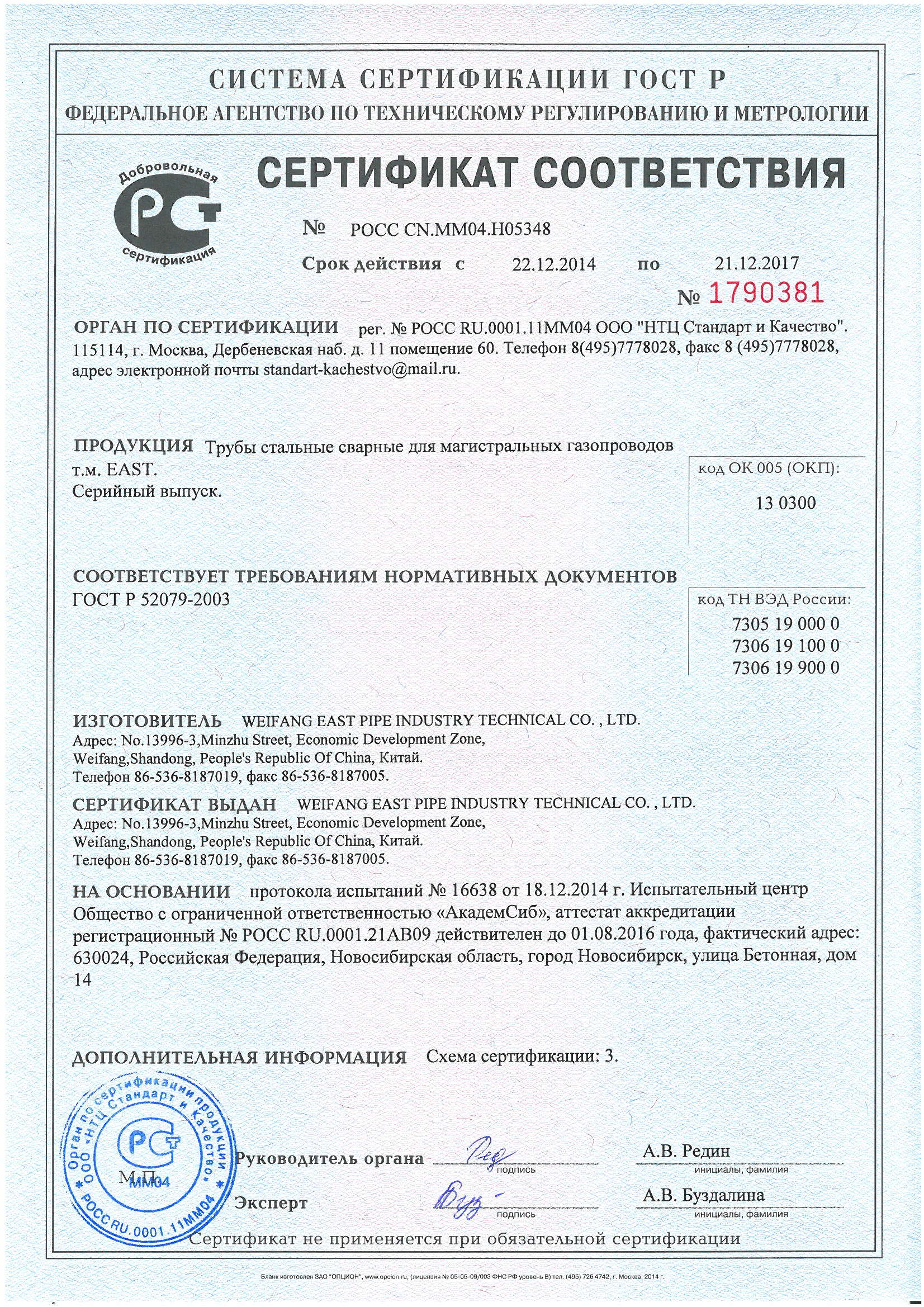

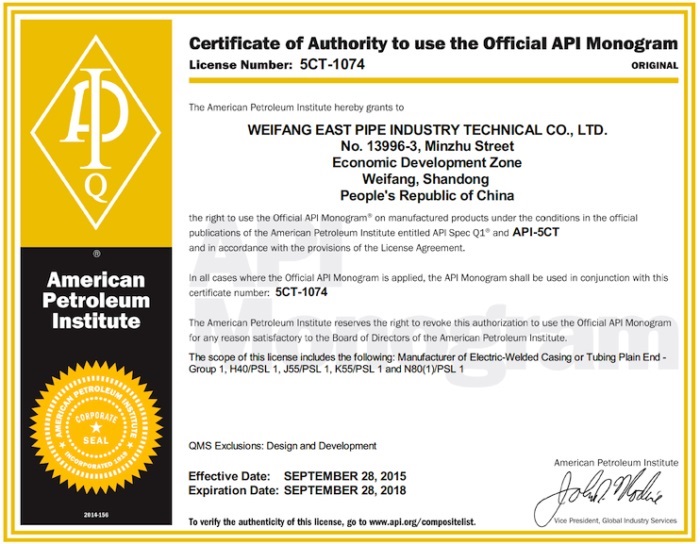

Our steel pipe production in strict accordance with the norms, raw materials are with China’s steel factory cooperation, our products are trustworthy.

Baoji Cigarette Factory Water Networks